Its an old high carbon steel from the 10XX steel series, it's generally used for knives and blades, the first two digits of the designation "1095" refer to the main two elements used in the steel, and the second two digits represent the percentage of carbon used In the case of " 1095 " the first digit " 1 " refers to carbon, the second digit " 0 " means that there is no second main elementThis sword is made of 1095 high carbon steel, clay tempered with a polished mirrorlike surface It is a very strong sword made with traditional methods, for multiple applications The blade is repeatedly heat treated and hand forged to remove impurities The clay temper process combines the ch $ Add to Sword BagBlade Hand forged and filed 1095 carbon steel Handle Carved and engraved copper with antiqued steel pins Description Kiridashi are small knives used throughout Japan for doing all sorts of tasks They are used in woodworking for marking and for detail tasks around the house

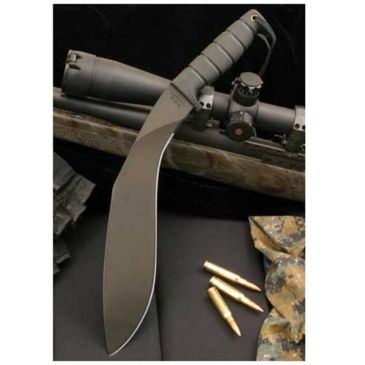

Ontario Tactical Kukri Smkw

Is 1095 carbon steel good

Is 1095 carbon steel good-The vast majority of knives produced here at Great Eastern Cutlery utilize 1095 High Carbon Steel Carbon Steel is a very traditional material which has several advantages over stainless steel such as edge retention, its willingness to take a keen edge, and its ability to gain a very high polishOutback 1095 High Carbon Steel American Bowie Blank Blade MSRP $ Was $6495 Now $5515 Add to Cart SALE White Deer Blank Blade 1095 Forged Steel Blank DIY Butcher's Chef Knife Limited Edition

Ka Bar Kukri Machete Knives Outdoor Knives Outdoor Survival Survival Torrin Wulflund Com

Specifications Overall Length 10 Inches Blade Length 475 Inches Blade Material Japanese 1095 High Carbon, 15N Alloy Steel Blade Thickness 5mm Blade Hardness 5560 HRC Rockwell Scale Tang Full Tang Sharpness & Functionality Very Sharp, Functional Blade Blade Features Blood Groove, SpayPoint Styled Profile, Butcher Knife Handle Length1095 Carbon Steel Information and Composition Condition This alloy been properly annealed and is in the soft condition You do not have to do any nonstandard wasteful processes before heat treating The steel must be heat treated to get to a hardened state Follow the heat treat recipe and the steel will get hard Ratings 22 = Maximum ToughnessDamascus knives blades are built from nickel and 1095steel It is tough but holds a poorer edge than 1095steel knives Damascus is more expensive but worth the price, while 1095steel is more economically viable So it is up to you while deciding between Damascus and 1095 3 Is 1095 Easy To Sharpen?

Overall, 1095 does prove to be a little more difficult to heat treat for some makers as it is hypereutectoid and best used with an accurate means of reading temperature and a fast quench oil (we recommend Parks 50) Those that have mastered heat treating 1095, however, have produced some of the most beautiful hamonsFind many great new & used options and get the best deals for 1095 High carbon steel blade Machete knife with leather sheath at the best online prices atIt is harder but more brittle than lower carbon steels such as 1055, 1060, 1070, and 1080

1095 CRO Van Steel is high carbon steel derived from the famous 1095 steel by adding more carbon, nickel, chromium, molybdenum, and vanadium Other names used to refer to this steel include Sharon Steel 1095CV, B (named so by Bark River), B (formal name according to American Iron and Steel Institute), Carbon V, 1095CV, and steelMr Volcano 3Pack Knife Blade Steel 1095 High Carbon Annealed Flat Stock Bar Blade Billets Blanks for Knife Making, Forging, BladeSmithing, BlackSmithing (12 inch x 15 inch x 3/16 inch) 47 out of 5 stars 398 $19951095 High Carbon NonStainless Steel is one of THE TOUGHEST steels available on the market It works well in fixed blade formats It is also popular with knife forgers Simple tool steel with 95 Carbon and little else in the alloy Makes good springs, knives, tools etc Much used in old time production knives

Amazon Com Ontario Knives Machete 12 5 Inch Tactical Knives Sports Outdoors

Esee Expat Knives Darien Machete 12 38 1075 Carbon Steel Micarta Handle

Our knife making approach is to use the latest in small shop manufacturing techniques to produce top quality blades to last a lifetime We are blade steel connoisseurs who like to use a wide variety of steels from classics like 1095 carbon steel to CPM This steel grade is based on the 1095 steel—another high carbon steel for knives—but with the addition of elements Vanadium, molybdenum, nitrogen, and chromium These additional elements set the two steels apart and give the CroVan steel better toughness and wear resistance than 1095 steel440C is a midrange Stainless Steel from the 440 Series (440 A, 440B and 440C) high in carbon (Has more than 1%, which makes the highest carbon steel of the 440 series), it offers excellent wear resistance and corrosion resistance, used for budget and midrange knives

China Cheap Price 1095 Carbon Steel Machete Machete M213 Youyou Factory And Suppliers Youyou

Condor Tool Knife Big Leaf Machete 13 51 1095 Carbon Steel Blade Micarta Handles Welted Leather Sheath Knifecenter Ctk3931 13 5hc Discontinued

Location Maine #2 1075 is tougher and faster to sharpen but 1095 beats it in edge retention and max hardenability The only real chemical difference is that 1095 has more carbon Both great steels though 1095 is generally the better knife steel It still takes a beating and the better edge retention is a plus1095 Carbon Steel Applications AISI SAE 1095 carbon steel can be made into steel billets, steel powder, which can be used as tool steel, blade steel, spring steel 1095 high carbon steel uses mainly include chef knife, kitchen knife, pocket knife, mower knives, Bowie knife, hunting knife, doctor blade, wear parts, various springs, plow beamsOrder 1095 Powder Steel, a fine granulated metal powder for making your own canister Damascus Available in a 5pound and 25pound tin

Ontario 1 18 Military Cutlass Machete 18 1095 Carbon Steel Blade Zinc

Made Military Grade Kukri Bowie Survival Knife Machete 1095 Carbon Steel U S A Factory Manufactured Chsalon Collectibles

Hand Forged Skinning Knife The IHK Skinner $ Details The Sojourner 1095 High Carbon Steel Hammered Polished Blade $ DetailsBlade Satin finished 1095 carbon steel, 60 Hrc Bolster Lignum vitae Handle Contoured burgundy Micarta secured with copper Loveless style rivets Description Jerry Goettig, out of Bend, Oregon, makes an amazing culinary knife Jerry has been making knives since 10 and uses both stock removal and forging techniquesWe are Expert in Making All Kind of Handmade Knives Including Horse File And Damascus Steel Cowboy, Bull Cutter, Lineman Knives, Hunting Knives , Skinner and Cross Leather Sheath For Cowboy Knives We are Making Them and Export them at worldwide

Tops Machete 230

Ontario 18 Machete Agrussell Com

How to Easily Heat Treat 1095 High Carbon Steel for Knife Making This video is part of The Complete Online Guide to Knife Making In this video we demonstra The knives are made in the USA Many cheap carbon steel blades, like Schrade (which I also like, btw) are made in China Bottom line it's true ESEE ships a higher priced 1095 knife However IMHO, this is because they do a few things to make it a higher quality complete knife system than some competitorsHome of blades presents top quality blades custom handmade top quality musso bowie knife product measurements over all length = 180" inches blade length = 1300

1

Ontario Knife Okc Kukri Machete 1095 Steel Blade Nylon Sheath

RMP Knife Blade Steel High Carbon, 1095 Knife Making Billets, 6" x 24" x 187", 1 per Pack RoseMetalProducts 5 out of 5 stars (134) $ 5295 FREE shipping Add to Favorites 1080 Steel (annealed ) TXKnifemakersSupply 5 out of 5 stars (559) $ 5 Add to FavoritesOntario OKC Heavy Duty Machete 22" 1095 Carbon Steel Blade with Zinc Phosphate Finish Polymer Handle and Handguard Black to Cart Ontario OKC Field Machete 18" 1095 Carbon Steel Blade with Zinc Phosphate Finish Polymer Handle and Handguard Black List8 3/8" overall One piece 1095 carbon steel construction 2 5/8" knife blade on one end and a 1 7/8" tomahawk/chopping blade on the other end (tactical head triple edge) Comes with two individual black leather sheaths May be used independently or with the TPHAKET01OF HAKET (Hawk and Knife Emergency Tool) set Made in the USA

Bark River Knives Ksf Machete 1095 Carbon Steel Ivory Micarta Scales

Sp8 Machete Pocket Knives Knives Heavenly Swords

1095 is carbon steel, very basic as it contains only two main elements, carbon, and manganese It's relatively hard with good wear resistance This steel lacks enough manganese for great toughness but is harder and flexible than many 10xx steels such as 1080, 1070, and 1060The combination of super strong zebra wood and high carbon steel makes this fixed blade camping knife invincible; 1095 is simple carbon steel featuring two alloying elements namely carbon and manganese It appears under the 10xx family of steels which are popular with knives as well as Japanese Katanas This steel features a high carbon content ranging between %, enabling it to take and hold a supersharp edge

Husa Knife Achang Battle Ready Hand Forged 1095 Carbon Steel Chinese Machete Dao Sword

Ontario Sp8 Machete Survival 10 1095 Carbon Sawback Blade Nylon Sheath Knifecenter 86

Notably, this includes knives with D2, 1095, , O1 and otherwise unspecified "high carbon" steel blades Some knife makers, such as Great Eastern Cutlery, use carbon steel in almost all of the knives they produce The generally cited virtues of carbon steel blades include ease of sharpening and ability to take a very keen edgeIt has a full tang, 4 3/8" 1095 high carbon steel blade with a matte finish and, make no mistake, it is keenly sharpThe 10xx series is the most popular choice for carbon steel used in knives as well as katanas They can take and keep a very sharp edge 1095, a popular highcarbon steel for knives;

Machete Billings Army Navy Surplus Store

Heavy Duty Machete Orange Walmart Com Walmart Com

Our 1095 is made again in Steel City Sheffield After the success of our made in GB 80CrV2, we have now expanded to include the popular 1095 high carbon steel Popular with both stock removal and forgers alike, 1095 is a great steel to get started in the world of knife and tool making Capable of higher hardness with decent toughness and a not too difficult heat treatment! 1095 crovan steel is a high carbon, low alloy tool steel with medium hardness The typical chemistry ranges for this grade are 1% carbon, 06% of Chromium, and 006% of Molybdenum (all by weight) 1095 crovan steel has the advantage of being very easy to machine because it does not harden too much when quenched in oil or aircooled from an austempering

Tops 170 Machete 1095 High Carbon Steel Tpmac170

10 Best Machetes Of 21 Hiconsumption

Messages 2,121 #3 1065 should be a very tough steel, medium edge durability and very easy to sharpen Since it was a hypoeutectoid steel it will need higher temp range on heat treat and longer soak time Not a very easy steel to begin with compare to something like 1084 or SK5 thoughOur 1095 is cold rolled and annealed with bright finish This material is most commonly used for forging various blades It contains a carbon content of 95% which helps to harden the steel and reduce the amount of wear and tear that a blade may experience over time10 rows Ontario OKC Field Machete 18" 1095 Carbon Steel Blade with Zinc Phosphate Finish Polymer Handle

Kukri Bowie Survival Knife Machete 1095 Carbon Steel Heavy Duty U S A Made

Ontario Knife 17in Kukri Machete W Kraton Handle Black Blade Plain Edge 29 Off W Free S H

Steels produced through particle metallurgy can cost 10 times as much as standard carbon steelsYes, less than 1% might not sound like a lot, but for steel, it is To give you an idea of how high this is, stainless steel only about 2% carbon This extra carbon makes this steel very hard and sharp, perfect for knives This is the reason why 1095 steel is so common in knives today But not everything is perfect 1095 is a great steel 1095 (and 1084, 1070, 1060, 1050, etc) Many of the 10series steels for cutlery, though 1095 is the most popular for knives When you go in order from , you generally go from more carbon to less, from more wear resistance to less wear resistance, and tough to tougher to toughest

1095 Carbon Steel Guide Medieval Swords World

Military Grade Kukri Bowie Survival Knife Machete 1095 Carbon Steel U S A Made 79 99 Picclick

High carbon steel has a factor of brittleness due to strong cementite network in the matrix but it does not prevent it from being the best knife steel Carbon steel is prone to rust that's why variant called 1095 crovan steel is used for daggerBuy Condor CN257HC for $23 with free shipping Condor Tool & Knife CTK257HC Mountain Pass Camp Knife 701 inch 1095 Carbon Steel Blade, Micarta Handles, Welted Leather Sheath at KnifeCenterTemporarily Out of Stock Put me on the Waiting List TPMAC170 TOPS Machete 17 1/4" overall 10 1/4" 1095 high carbon steel blade with ash gray finish Full tang Black linen micarta handles with black cord lanyard Black nylon belt sheath with front

Collectible Fixed Blade Knives Okc Military Grade Machete Sword Full Tang 1095 Carbon Steel Made In U S A 18 Oa Modern Fixed Blade

Condor Tool Knife Amalgam Machete 11 72 1075 Carbon Steel Blade Walnut Handles Welted Leather Sheath Ctk2817 11 7hc Fstop Lights

1095 Steel is a basic form of carbon steel and is most commonly used in the construction of various kinds of knives It has a carbon content of 95% which serves to harden the steel and reduce the amount of wear that a blade will experience over time Despite the reduction in wear created by the high presence of carbon, 1095 steel is not as tough as other types of steel1095 Steel in Knife Production Knife makers choose 1095 because of its hardness, workability, easy sharpening, and modest price Stainless steels can cost four times as much as 1095 steel;Yes, Carbon steel is easy to sharpen

Survival Jungle Machete Knife Us Military Issue 1095 Carbon Steel Made In Usa For Sale Fleetwoodmac Net

Ontario Camper Fixed 1095 Carbon Steel Blade One Piece Black Handle Machete 8510 Ebay

TOOL STEEL SERIES 1095 High Carbon Tool Steel is also referred to as, "Cutlery Spring Steel", and is well known for its use in manufacturing commercial saw blades This extreme high carbon steel hones to a razor sharp edge (better than any stainless steel), retains its edge (better than most stainless steels), and is easier to sharpen, (compared to stainless steel)

Okc Ontario Sp 8 Survival Machete W Nylon Sheath

Okc6145 Okc Machete Military 18 1095 Carbon Steel Blade Syn Handle Free Shipping Over 49

16 1 Seo Handmade Full Tang 1095 High Carbon Steel Small Machete Hunting Knife 65 00 Picclick

Gerber Carbon Steel Machete With 8 In Steel Handle In The Axes Department At Lowes Com

What Is The Best Survival Machete In 21 All Knives

A 1095 Light Chopper Machete Munrocraft

Ontario Knife Co Traditional Cutlass Machete 12 Plain Edge Drop Point 1095 Carbon Steel Blade Full Tang Polymer Handle Black Finish Ct1

Ka Bar Kukri Machete Knives Outdoor Knives Outdoor Survival Survival Torrin Wulflund Com

Gurkha Kukri Knife High Carbon 1095 Steel Machete Knife Sword Antique Style 19 Battling Blades

Ontario Tactical Kukri Smkw

Stunning Custom Made 1095 High Carbon Steel Blade Machete Full Combat Knife Ebay

Ontario Knife Company 22 Heavy Duty Machete Black Newegg Com

10 Best Machetes Of 21 Hiconsumption

Ontario Okc Machete Kukri 64

Sog Machete In The Specialty Landscaping Tools Department At Lowes Com

The Best Survival Machete For The Wild Secrets Of Survival

Stunning Custom Made Carbon Steel 1095 Battle Cleaver Machete Chopper Knife Ebay

Husa Knife Achang Battle Ready Hand Forged 1095 Carbon Steel Chinese Machete Dao Sword

Condor Tool Knife Big Leaf Machete 13 51 1095 Carbon Steel Blade Micarta Handles Welted Leather Sheath Knifecenter Ctk3931 13 5hc Discontinued

Ontario 1 18sbk Machete Sawback 18 W Sawback No Sheath Osograndeknives

Cold Steel 97kms Kukri Universal Steel Tactical Machete Blade Replica With Protective Sheath Black Target

Condor Tool Knife Big Leaf Machete 13 51 1095 Carbon Steel Blade Micarta Handles Welted Leather Sheath Knifecenter Ctk3932 13 5hc

Bowie Knife Handmade 1095 Steel Machete Knife Sword 17 Battling Blades

Custom Handmade Full Tang Combat Bowie Machete Custom Made 1095 High Carbon Steel Details About Wow Knives Swords Blades

Custom Handmade Full Tang Combat Bowie Machete Custom Made 1095 High Carbon Steel Details About Wow Knives Swords Blades

Bowie Knife Handmade 1095 Steel Machete Knife Sword 17 Battling Blades

Usa 1095 High Carbon Machete Blank Etsy

Cold Steel Black Bear Bowie Machete With Polypropylene Handles And Black Baked On Anti Rust Matte Finish 1055 Carbon Steel Clip Point Plain Edge Blades Smkw

Esee Expat Knives Darien Machete 12 38 1075 Carbon Steel Micarta Handle

High Carbon Steel Machete Knife Sheepsfoot Blade Solid Etsy

Amazon Com Dtyes Japanese Samurai Katana Sword Real Swords For Men Samurai Sword Sports Outdoors

10 Best Buy Machetes On Amazon Knife Handle Making Machete Survival

Husa Knife Achang Battle Ready Hand Forged 1095 Carbon Steel Chinese Machete Dao Sword

Gurkha Kukri Knife High Carbon 1095 Steel Machete Knife Sword Antique Style 19 Battling Blades

Bowie Knife Handmade 1095 Steel Machete Knife Sword 17 Battling Blades

Condor Big Leaf Machete Fixed Blade Natural Micarta 13 51 Satin Ctkhc Osograndeknives

Ontario Kukri Machete Qn 64

Tops 230 Jungle Machete 1095 High Carbon Steel Tpmac230

Husa Knife Achang Battle Ready Hand Forged 1095 Carbon Steel Chinese Machete Dao Sword

Alpha Custom Hand Forged 1095 Steel Machete Knife Brown Black Etsy

Tops Elch 01 Green Black El Chete Machete Micarta Fixed Blade Knife 1095 Carbon Acid Rain

Dtyes Full Handmade Japanese Katana Ninja Sword Machete 1095 High Carbon Steel Damascus Steel Blue Black Yellow Purple Baked Finish Blade Heat Tempered Sharp Double Edges Wooden Scabbard

Ontario Knife Okc Kukri Machete 1095 Steel Blade Nylon Sheath

Ontario 1 18 Military Machete 6145 At Ontario Knife Store Com

Ontario Okc18or 18 Machete Orange

Condor Leaf Machete 13 5 1095 Carbon Steel Blade Micarta Handles 634 Ebay

Gurkha Kukri Knife Handmade High Carbon Damascus Steel Machete Knife Sword 16 Damascus Steel Leather Sheath 1095 Steel

Condor Tool Knife Big Leaf Machete 13 51 1095 Carbon Steel Blade Micarta Handles Welted Leather Sheath Knifecenter Ctk3932 13 5hc

Stunning Custom Made Carbon Steel 1095 Battle Cleaver Machete Chopper Knife Ebay

Ontario Sp8 Machete 10 1095 Black Carbon Steel Blade Kraton Handle

Bl0bkk1fo0pyim

Q Tbn And9gcr5qwzh Moghghjbxub 63t4kug8vbfykcqn3vlvs74vkbiiftl Usqp Cau

U S A Moore Maker Machete 1095 Carbon Steel Blade

Pin On Michael Hamlin Bassmaster Hopeful

Bark River Knives Ksf Machete 1095 Carbon Steel Ivory Micarta Scales

Husa Knife Achang Battle Ready Hand Forged 1095 Carbon Steel Chinese Machete Dao Sword

Custom Handmade Fixed Blade 1095 High Carbon Steel Survival Etsy

Machete 230 Walmart Com Walmart Com

Esee Junglas Latin Machete 16 5 Overall 1095 Carbon Steel Esjunglas

Ontario Ct2 12 Sawback Traditional Cutlass Machete 97 At Ontario Knife Store Com

1

Custom Handmade Full Tang Combat Bowie Machete Custom Made 1095 High Carbon Steel Details About Wow Knives Swords Blades

8 Best Machetes Reviewed In 21 Incl Survival And Tactical Matchetes Outdoor Empire

25 5 2 Pc Tactical Full Tang Carbon Steel Ninja Sword Machete Samurai Katana Amazon Com

Collectible Fixed Blade Knives Wow Machete Custom Made 1095 High Carbon Steel Full Tang Combat Bowie Modern Fixed Blade

China Cheap Price 1095 Carbon Steel Machete Machete M213 Youyou Factory And Suppliers Youyou

Survival And Rescue Machete W Sheath Devil Dog Depot

Ontario Knife D Handle Machete At Cspforestry Com

Bug Out Survival Ontario Knife Lc 18 A Good Basic Machete

Trademark 25 6793 Military Machete Rubber Grip Handle Black 19 Inches Overall 12 Inch Blade 1 5

1

The Best Machetes Of 21 Best Self Defense Knife

Ka Bar Kukri Machete 1095 High Carbon Steel 1249

A Look At The New 21 Condor Lineup Knife Newsroom

Tops Machete 170 Gray 1095 High Carbon Steel Micarta Handle Scales Molle Compatable Nylon Sheath Mac170 New Graham Knives

7 Best Machetes Of 21 High Quality Machete Knife Reviews

Combat Cleaver Trench Knife And Sheath Fire Kissed 1095 Carbon Steel Blade Brass Knuckle Guard Handle

Ontario Knife Company Camper Fixed 12 Machete Black Zinc Phosphate Finish 1095 Carbon Steel Blade Shatterproof D Handle 8511

0 件のコメント:

コメントを投稿